Mathews Hydroscan Data Logging System

Tubing and Valve Testing Modes Available

With medium and large oil producers requiring more and more access to data, we took the opportunity to design the most comprehensive, feature rich data logging system available for the downhole tubing testing industry. We combined tubing specific functionality with a universal pressure over time charting option to give you the flexibility you need.

And for those smaller producers who don’t require data logging, the Mathews HydroScan system is the perfect insurance policy. Now you have an absolute record that every test reached the target pressure and was held for the correct amount of time. And you can eliminate any concerns that a customer may have about over-pressuring their assets.

When it comes to logging data on production tubing tests, the HydroScan system is second to none.

Features:

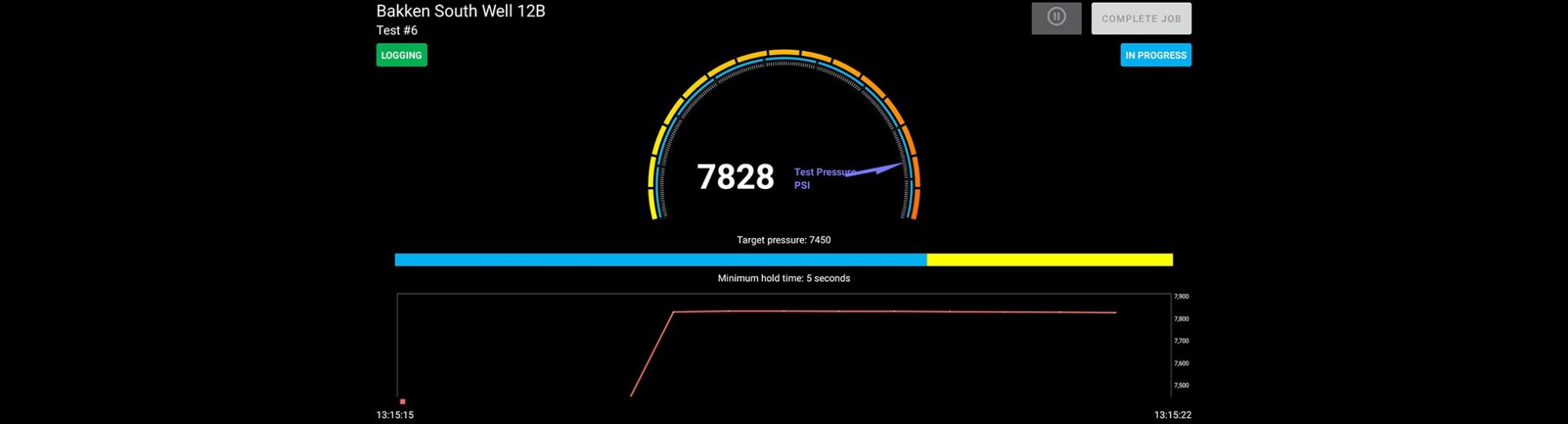

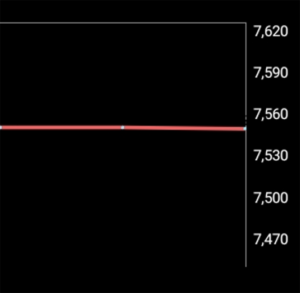

One of the more unique features of the HydroScan system is its live digital charting with auto-zoom. Instead of pinching or pushing buttons to change the screen, the programming automatically zooms in to give the operator the best view of the test in progress. Now they can be 100% confident that if they call it good.. it‘s good.

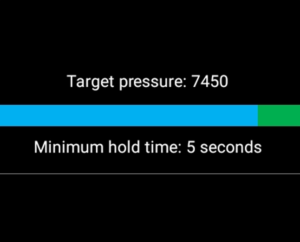

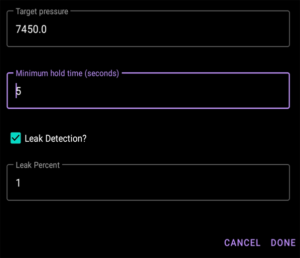

With the ability to set a target pressure and minimum hold time, operators can now guarantee that a test is held for the required length of time without any guesswork. When an adjustable threshold is broken, the system begins monitoring pressure data for the target to be exceeded. At that point, the status bar turns blue to start the timer and then green when the hold time has been achieved. 100% operator friendly.

Another unique feature of the HydroScan system is its leak detection capability. By checking the box and setting the desired percentage, an operator now has a mathematical method of determining when a leak is occurring. If the pressure falls more than the preset percentage before the hold time is reached, then a leak is indicated. A retest button also becomes visible in case the leak can be corrected.

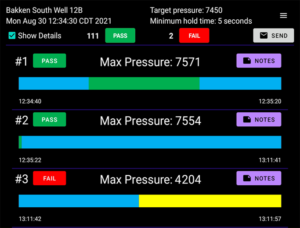

The summary page header provides relevent info like well name, date, target pressure, and required hold time. It also shows the number of tests passed vs failed and offers an email send button to quickly share the test results. With the “Show Details” checkbox, pass, fail, and leak status for each test are displayed, as well as maximum pressure reached and the exact time between tests. Any recorded notes can also be viewed from this screen.

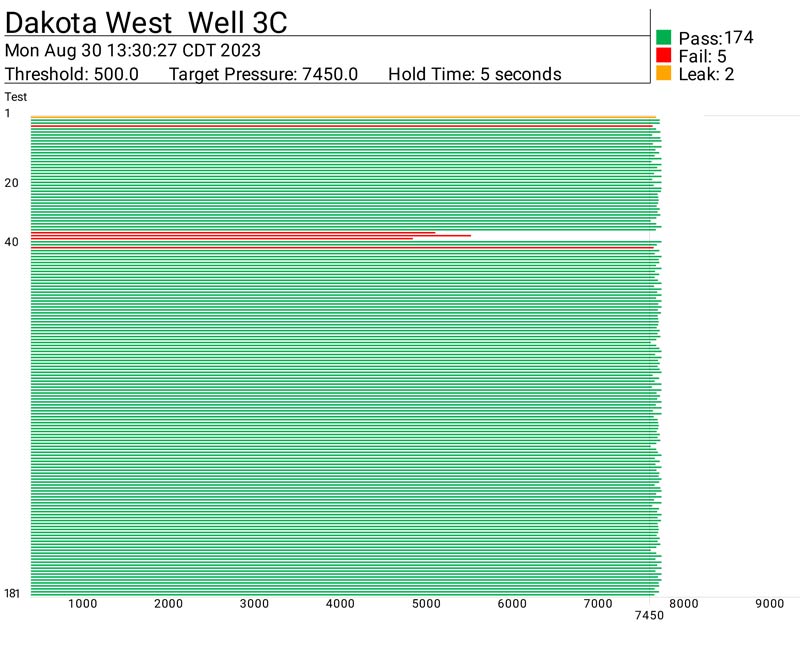

Well Report - Vertical Summary

Another important feature of the Mathews HydroScan Data Logging System is the Vertical Summary Page that displays each pass, fail, and leak test result in an easy to read format. This allows producers to quickly identify problem areas in their tubing strings and make important decisions about rod guides, chemical programs, and other measures that can maximize efficiency and extend the time before the next well servicing.

And in the latest update, we’ve even made it possible to change the parameters of a tubing testing job on the fly. If the tubing string requires different target pressures, simply change the value on the edit screen and your summary reporting is updated automatically.

When it comes to downhole tubing testing, there aren’t too many opportunities to gain a competitive edge. With the HydroScan system, you can position your service company as the provider who is dedicated to keeping pace with the the latest technology. When you can offer data acquisition that not only meets, but exceeds expectations… you become the logical choice.

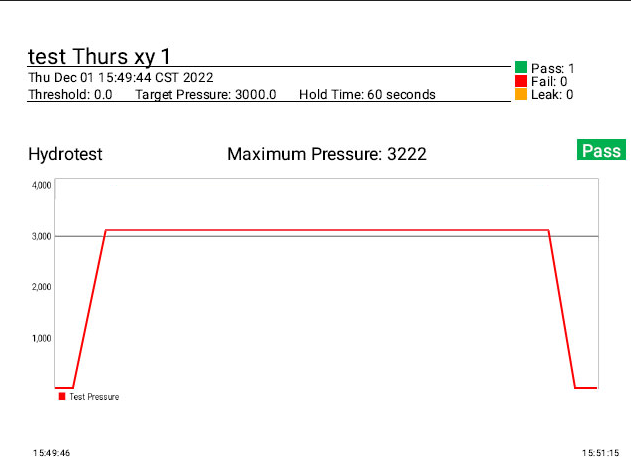

Pressure over Time Charting

When you’re working with other oilfield iron and only need a standard test report showing pressure over time, the HydroScan Data Logging System makes it easy. Simply slide a switch on the job setup screen and enter your target pressure and hold time. Once your test requirements have been met, the green “Pass” indicator will illuminate, letting you know that the pressure can be released. As with the tubing testing reports, the two-axis chart can be exported by email or saved to usb drive with the touch of a button.

NIST Certified Calibration

.10% Accuracy

Multiple Samples per Second

Leak Detection Logic

Hold Time Counter

Target Pressure Indicator

Live Graph (Auto Zoom)

Quick View Summary

Comprehensive PDF Reporting

Operator Friendly